The internet is a remarkable source for all manner of things. This includes an almost dazzling supply of 3D printable files for all different types of tanks, guns, terrain pieces etc. in any scale you fancy!

I started modestly with a search in Thingiverse that revealed a collection of 1/200th AFVs created by Marco Bergman, and shared most generously, free of charge to anyone who wants to use them privately. (https://www.thingiverse.com/thing:232248)

I decided to start with the US M1A1 so downloaded the .stl file and converted it to .gcode in Cura.

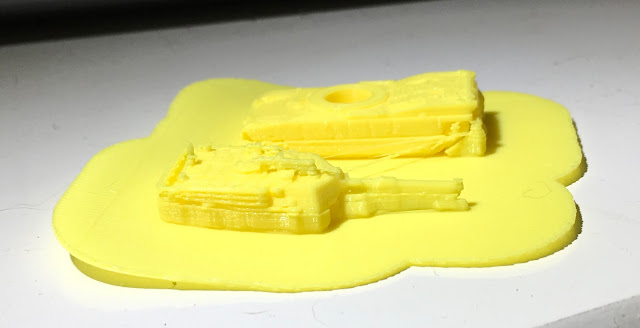

The file as downloaded had the hull and turret stood on end, gun and bow facing upwards. This is probably a sensible way to go as many printers (mine included) have quite limited print bed sizes. However for reasons known only to myself, I decided to lay both parts flat and print them side by side. The picture below shows how that progressed.

- The print started with creating a "raft" to support the finished parts. This helps to ensure good adherence to the bed (but doesn't guarantee it!)

- The supporting ribs for the underside of the turret are starting to appear here. These are easily re,moved afterwards.

- Another view of the turret building up layer by layer

- The almost completed turret has now appeared

- The settings used on my printer, showing the 1.75 hour build time!

|

|

This side on shot illustrates the supporting material that fills the turret underside

|

For first printing - good result

ReplyDeleteTry using the glue pencil on the printer table. This will increase the plasticity of the plastic to the table. Still many use a varnish for hair

Thanks O3. I have since covered the print bed with blue masking tape and I am using a glue stick with much better results.

ReplyDeleteI would say that this turned out well. Obviously you could fine tune it in terms of smaller layers. There are also tricks you can do with model orientation, which make the striations from layers less obvious. (notice how the armored skirts do not have any visible lines)

ReplyDeleteI’ve been experimenting with printing FV432 apcs stood up on their ends to reduce the ribbing effect. Seems to work well

ReplyDeleteFV432!? do not share the link? on tingiverse not very good models lined

ReplyDelete